Cinnamon production and how cinnamon is made are interesting questions many people seek for answers. This article below will provide the step-to-step process behind cinnamon production.

Table of contents

A general overview of cinnamon production

A brief overview of cinnamon production is a fundamental need for anyone wanting to do business in this cinnamon market.

Definition of cinnamon production

Cinnamon production is the process of harvesting raw cinnamon resources and processing them into useful cinnamon goods with customized packaging. The diversity of cinnamon goods, as well as the quality and qualification of cinnamon products, are the most significant benefits of cinnamon production in factories over traditional techniques.

Cinnamon production: strengths and potential

- Cinnamon production is considered an inherently sustainable market since cinnamon tree forests flourish in tropical woods without much human interference, there is no need to clear land, add pesticides, or disrupt ecosystems for these crops. Then, minimize the cost of other portions in production of cinnamon significantly.

- Furthermore, cinnamon provides long-term earnings because it only needs to be grown once and maybe utilized and reused for 10 to 15 years, even 20 years if properly cultivated.

- As a result, cinnamon production has a lot of room for improvement, in the long run, benefiting both farmers and producers.

Typical types of cinnamon products

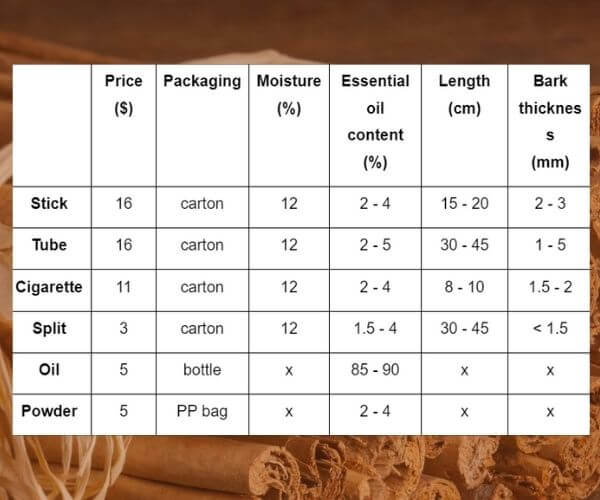

Because of the increasing growth of cinnamon production, there is now a wide range of cinnamon goods available. Cinnamon goods are classified into seven types: cinnamon sticks, cinnamon tubes, cinnamon cigarettes, cinnamon splits, cinnamon oils, cinnamon powder, and cinnamon broken.

Cinnamon sticks are considered a high-segment product, whereas cinnamon breaks are considered a low-segment commodity. The table below illustrates the distinctions between common cinnamon products.

Main distribution of cinnamon production

Overall, Vietnam, China, and Indonesia are the top cinnamon-producing countries in the world, especially Cassia cinnamon with 31,429 tonnes, 72,531 tonnes, and 91,242 tonnes respectively according to the latest statistics of FAOSTAT. Plus with the advantage of being near the raw material source, these countries provide large and innovative cinnamon production.

- In Vietnam, Yen Bai, a province in the middle of Vietnam’s northern mountainous and midland area, is the best source for cinnamon production in the country. Yen Bai has 50 hectares allocated to cinnamon cultivation, with Van Yen district alone covering 40 hectares. Yen Bai is the place where the mass of cinnamon in Vietnam converges due to the priority of surviving on discolored sites, eroded soil, and a tropical monsoon climate. Furthermore, Quang Ninh, Lang Son, Quang Nam, and Tuyen Quang are provinces with a progressive increase in cinnamon output size.

- In Indonesia, Kerinci, an island in Sumatra, is regarded as the hub of cinnamon production in the country, if not the globe. Kerinci Regency is a farming and manufacturing zone, particularly for production of cinnamon, which explains why this location focuses on the large cinnamon number and benefits for cinnamon production. Fertile soil is a present from Mount Kerinci, Indonesia’s tallest volcano.

- In China, cinnamon is grown within a few southeastern Chinese regions, including Guangdong and Guangxi. In two instances, geography benefits play a vital influence in cinnamon production. Guangdong is a South Chinese coastal province on the north bank of the South China Sea, whereas Guangxi is an independent area bordering Vietnam (Hà Giang, Cao Bang, Lang Son, and Quang Ninh Provinces). This unique position not only aids production of cinnamon but also facilitates delivery to other countries.

The main process of cinnamon production

Cinnamon production is a process requiring many stages to guarantee quality and quantity. The piece below will demonstrate the integral parts during this process in general and cinnamon oil production alone.

Fundamental steps in cinnamon production

Though each cinnamon product type and each cinnamon productions company have different practices, there is a list of steps needed to follow.

- Step 1: Harvesting. The prime time for harvesting cinnamon is right after finishing each rainy season when the dampness causes the bark to peel more simply. When peeling off certain trees, it is important to notice that the bark is not cracked, fractured, sliced, or adhered to the trunk. To serve the large cinnamon production, cinnamon barks are gathered biannually in the spring and autumn since they are at least two years old.

- Step 2: Processing. Tender stems, outer barks, and fragments of cut barks (quills) are the parts of the production of cinnamon factory that must be handled at this stage. In general, processing accounts for more than half of the cost of cinnamon production due to the laborious nature of peeling bark from stems with professionals. Cinnamon’s quality is determined by how effectively the bark is separated from the stems.

- Step 3: Drying. In cinnamon production, cinnamon needs at least four to five days to dry. When the cinnamon sets, it curls up into small scroll-like shapes. Dryers, both gas, and electric, are required in humid and wet weather to guarantee the quality of cinnamon productions.

- Step 4: Grading. Grading means evaluating and scrutinizing the appearance and the aroma of the product based on the previous standards of the cinnamon production process. For example, the standard for cinnamon sticks is at least 12% moisture and 2% essential oil content.

- Step 5: Grinding. In some production of cinnamon processes, some companies exclude this stage because the main purpose of this step is to heighten the value of the product in an aesthetic way. Each type of cinnamon product has a different standard. For instance, the standardized length for cinnamon sticks is at least 15 centimeters while cinnamon tubes are 30 centimeters.

- Step 6: Packaging and Labeling. Cinnamon is packaged in a variety of forms, including boxes, PP bags, cartons, and bales. Containers with passive ventilation must comply with reduced water content limitations for commodities, packing, and container floors.

- Step 7: Storing. Choosing a location that is cool, moist, and devoid of pets is a must-have need for storage in cinnamon production. One of the greatest methods to keep cinnamon fresh in cinnamon production is to store it in sealed containers. Cinnamon can remain in a sealed container for 2-3 years, however, it may lose its strong flavor and fragrance with time.

Process of cinnamon oil production

Aside from the integral parts, cinnamon oil has some distinct features in production of cinnamon known as the extraction section. The extraction method widely used in the production of cinnamon oil is steam distillation. In general, it includes a list of phrases:

- Stage 1: Processing.

- Stage 2: Separating raw materials to load into a distillation reactor.

- Stage 3: Heating, then distilling.

- Stage 4: Maintain distilling temperature at 80-110 degrees Celsius, steam pressure at 0.06MPa-0.08MPa for 2-3 hours.

- Stage 5: Cooling.

- Stage 6: Separating oil from water.

- Stage 7: Standing.

- Stage 8: Refining

- Stage 9: Packaging and labeling the final product.

Factors influencing the products’ price in cinnamon production

During the production of cinnamon, there are many elements impacting the price of products, which comprise demand, supply, SPEC, and government policies.

Demand factor in cinnamon production impacting the products’ price

During recent years, the demand for cinnamon has been on the rise because of the spice blend and “go organic” tendency during the spread of Covid – 19 and the clearest evidence is the import-export mismatch.

- To be specific, as per OEC, the import value of Bangladesh accounting for $30.7 million is over 600 times higher than the export value of this country with $50.8 thousand. The similar trend is also seen in many countries such as India, United States and Mexico.

- This phenomenon leads to the increase of cinnamon products lately. Besides, the rising price of cinnamon products still results from the innovation of cinnamon production due to technology application.

Supply factor in cinnamon production impacting the products’ price

Now, cinnamon developed as a promising star in the spice market with large overall output. However, the deleterious hit of the COVID – 19 pandemic has slightly lowered the overall output of cinnamon production. From 2017 to 2020, according to FAOSTAT, the global quantity of cinnamon dropped by 199.766 tonnes from 223,506 tonnes to 222,122 tonnes. The imbalance of supply and demand in production of cinnamonleads to the gradual growth of cinnamon price.

SPEC factor in cinnamon production impacting the products’ price

SPEC in cinnamon production, or specification, is extremely important in determining the price of cinnamon products. The key factors influencing the pricing of cinnamon products are appearance, fragrance, moist, and essential oil content. The higher the essential oil content and moisture level, the higher the price of cinnamon products. This pattern also applies to the appearance and aroma of cinnamon products.

Government policies in cinnamon productions impacting the products’ price

Because of the influence on tariffs, taxes, and logistical charts, government policies are still another factor that contributes to the price of cinnamon production.

For example, unlike Indonesia, which has chaotic politics and a coup, Vietnam has strong institutions and no wars, as well as a dynamic economy that is predicted to expand the quickest in Asia in the next years, thus the price for all exporting goods is comparatively low. Furthermore, with the help of the EU-Vietnam Free Trade Agreement (EVFTA), which is set to enter into force in early August 2020, the export price eliminated 99 percent of all tariffs to European areas.

Qualified cinnamon production from top reliable companies

How to find trustworthy companies having standardized cinnamon production is a burning question for anyone interested in the cinnamon market. Here are some recommendations you should not overlook.

K- Agriculture Factory

Viet Agri Wholesale Company, belonging to K – Global, is one of the proposed cinnamon exporters exporting high-quality agricultural products from Vietnam to the rest of the globe with qualified cinnamon production. Being known as a popular wholesaler of premium agricultural commodities from Vietnam, with a capacity of 15000 tons per month and a storage capacity of 21500 tons, the dissemination of Viet Agri Wholesale Factory has expanded 80 countries across the world throughout its 25-year experience. Thanks to the support of the Ministry of Industry and Trade, Viet Agri Wholesale Factory always ensures the highest quality products of cinnamon and standardized cinnamon production.

Contact:

Phone: +84961504190 (Whatsapp Available)

Website: vietnamesecinnamon84.com

Email:

Herbs N Spices International Co.,Ltd

Herbs N Spices International Co., Ltd is a multinational company with offices in many countries, including India, Vietnam, Indonesia, China, Brazil, Nigeria, and Mexico. This corporation offers high-quality items in the fields of spices, herbs, tea, dried fruits, and agricultural products, including cinnamon products. Herbs N Spices has built trustworthy and long-term connections with an innovative cinnamon production, a broad network of buyers and suppliers based in South Asia, the United States, South America, Europe, the Middle East, and Africa. Over the years, this company has built a reputation for providing a unique combination of cinnamon production quality, value, and trust in order to meet all of our venerable clients’ requests.

HAGIMEX JSC

Founded in 2005, Hagimex is a leading manufacturer selling agricultural goods with the mission of embracing the genuine natural tastes of Vietnam’s tropical ingredients in each product as freshly collected to fulfill the taste of varied clients all over the world. This firm is regarded as the first company in Vietnam to approve cinnamon production for the BRC and IFS systems, the most prestigious worldwide food safety initiatives for cinnamon productions. Reformed its cinnamon production from 2015 to catch up the global standard, Hagimex cinnamon products are now sold in over 40 countries.

To sum up, it is undeniable that cinnamon production is a process requiring many stages and requirements. For anyone interested in selling and buying cinnamon products, hope this article provides you with necessary information about how cinnamon is made.